BS EN 1387: 1985

Screwed and socketed steel tubes and tubular sand for plain end steel tubes suitable for welding or for screwing to BS 21 pipe threads

1.1 Scope

This British Standard specifies requirements for screwed and socketed steel tubes and tubulars and for plamn end steel tubes suitable for welding or for screwing to BS 21 pipe threads,This standard is applicable to tubes of nominal size DN 8 to DN 150 in three series of thickness,designated light,medium and heavy.

1.2 Definitions

For the purposes of this British Standard the following definitions apply,

1.2.1 nominal size (DN)

a numerical designation of size which is common to all components in a piping system other than components designated by outside diameters or thread size. It is a convenient round number for reference purposes and is only loosely related to manufacturing dimensions

1.2.2 tube

a long hollow,open-ended object of circular cross section

1.2.3 socket

the screwed coupling utilized in joining the tubes together

1.2.4 tubulars

pieces,nipples,long screws,bends,springs and return bends.

1.2.5 length of screwed and socketed tube

1.2.5.1 exact length

the length of tube exclusive of the socket

1.2.5.2 length,other than the exact length

the overall length when one socket has been fitted

1.2.6 standard length

the nominal length of a pipe component which by virtue of custom and practice has become the normal length to which the component is supplied

1.3 Designations

1.3.1 Tubes

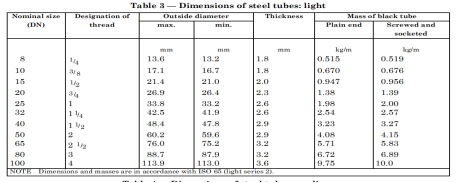

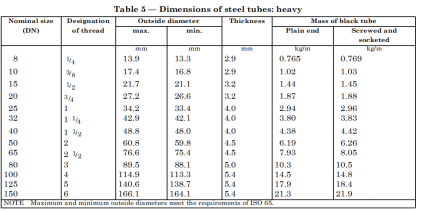

Tubes shall be designated by the number of this British Standard,the nominal size(DN)and thickness series as given in Table 3,Table 4 and Table 5 together with the type of end finish(plain or screwed ends),e.g.BS 1387 DN 20 medium series,screwed and socketed tube.

1.3.2 Tubulars

Tubulars shall be designated by the number of this British Standard,the nominal size (DN),thickness series,type of tubular and,where appropriate,their length.In addition,bends and springs shall be designated by their type reference(see Figure 6 and Figure 7),e.g.BS 1387DN 20 medium series,bend type 1.

1.3.3 Sockets and backnuts

Sockets and backnuts shall be designated by the number of this British Standard and the respective nominal size (DN)of the tube for which they are intended,e.g.BS 1387 DN 20 backnut.

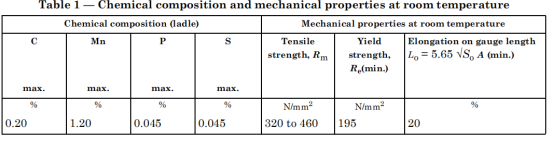

2. Chemical composition

The chemical composition of the steel shall comply with Table 1.

2.2 Mechanical properties

The mechanical properties at room temperature shall be as given in Table 1

2.5 Dimensions and tolerances

2.5.1 Dimensions

The dimensions of tubes shall be as given in Table 3,Table 4 and Table 5, Dimensions of sockets shall be as given in Table 6.

2.5.2 Tolerances

The tolerances on the outside diameter,thickness,mass and length shall be as follows.

a)Outside diameter.Light tubes as given in Table 3 Medium and as given in Table 4 and heavy tubes Table 5 respectively

b)Thickness.

Light tubes-8%

Medium and heavy tubes -10%

c)Mass.The mean consignment mass for quantities of 150 m and over of one size shall not deviate by more than±4 %o from the mass of the consignment calculated from the masses given inTable 3,Table 4 and Table 5 as appropriate. No single tube shall deviate by more than+10% and -8%from the mass given in Table 3,Table 4 and Table 5 as appropriate.

d)Length(see note).

1)Random lengths.When random lengths are ordered,tubes shall be supplied in one of the following ways:

a) in random lengths from 4 m to 7m;

b)(for orders of over 150 m of any one size of tube)in random lengths from 4 m to 7 m but including short random lengths from 1.8 m to 4 m provided that the number of such lengths does not exceed 7.5 % of the total number of lengths for DN 65 to DN 100 inclusive,and 5 %for all other sizes.

c) as for(b)but including tubes with two lengths joined together to make a random length,provided that the number of such jointed lengths does not exceed 7.5 % of the total number of lengths for DN 65 to DN 100

inclusive and 5 % for all other sizes.

2)Mill lengths.When mill lengths are required tubes shall be supplied in lengths of 6.4 m minimum.No tube shall exceed this length by more than 150 mm.

3)Approximate lengths.Where approximate lengths are required,either for screwed and socketed tubes or for plain end tubes,each tube shall be within±150 mm of the specified length.

4)Exact lengths.Where exact lengths are required,either for screwed and socketed tubes or for plain end tubes,each tube shall be within+6 mm of the specified length.